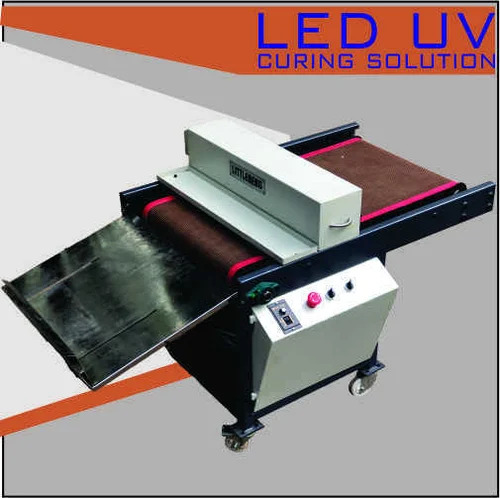

UV LED Curing

UV LED Curing Specification

- Power Supply

- Electric

- Product Type

- UV LED Curing

- Input Voltage

- 220 Volt (V)

- Application

- Industrial

- Warranty

- 1 Year

- Size

- Standard

- Rated Voltage

- 220 Volt (V)

- Usage & Applications

- Industrial

- Phase

- Three Phase

- Features

- Good Quality

- Material

- Mild Steel

- Frequency

- 50 Hertz (HZ)

UV LED Curing Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 7 Days

About UV LED Curing

UV LED Curing is an advanced and energy efficient curing technology used for instant curing of inks coatings adhesives and resins across printing electronics automotive packaging and industrial applications. This system uses high intensity ultraviolet LED light to deliver fast and uniform curing without generating excess heat making it ideal for heat sensitive materials. UV LED Curing offers long operational life low power consumption instant on off functionality and minimal maintenance compared to traditional UV lamps. It improves production speed enhances surface finish and supports eco friendly manufacturing by eliminating mercury and reducing energy costs making it a reliable solution for modern high performance curing requirements.

FAQs Of UV LED Curing

What is UV LED Curing used for ?

UV LED Curing is used for curing inks coatings adhesives and resins in printing electronics medical automotive and industrial manufacturing processes.

How does UV LED Curing work ?

It works by emitting ultraviolet light at specific wavelengths that trigger a photochemical reaction causing materials to cure or harden instantly.

What are the advantages of UV LED Curing over traditional UV systems ?

It offers faster curing lower energy consumption longer lamp life minimal heat output and no mercury usage.

Is UV LED Curing suitable for heat sensitive materials ?

Yes it produces very low heat making it ideal for plastics films and other heat sensitive substrates.

Does UV LED Curing require high maintenance ?

No it requires minimal maintenance due to its long lifespan and stable light output.

Is UV LED Curing environmentally friendly ?

Yes it is eco friendly as it consumes less power and does not use hazardous materials like mercury.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS